The Magnificent – Bogibeel Rail-cum-Road Bridge!

Describe the bridging and project history?

Bridging River Brahmaputra has always been a daunting task. The river has been traditionally considered extremely difficult for bridging due to various reasons including it’s ferocious and unpredictable behaviour, high currents and turbulent waters, widespread erosion of the banks, very short working period and high seismicity and remoteness of the area.

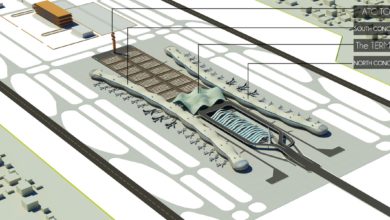

Bogibeel Bridge: Bogibeel Bridge is a combined road and rail bridge in the Dibrugarh district of the north eastern Indian state of Assam. When completed, the 4940.5 m long bridge will become the longest bridge of its kind in India.

The bridge will provide connectivity to nearly five million people residing in Upper Assam and Arunachal Pradesh. It will also give easy and direct access to the upper Assam from the rest of the country through the North bank, in contrast to the current route through Guwahati in the South bank -which is long and tortuous. Due to its location, the bridge will be of strategic importance to India as it will significantly enhance India’s ability to transport troops and supplies to its border in Arunachal Pradesh.

Project History

The project obtained approval of the federal Cabinet Committee on Economic Affairs (CCEA) in September 1997 and construction began in April 2002.

For the purpose of building the bridge, Indian Railways had to construct the expanse of the Brahmaputra river from 10 kilometres to 5 kilometres. This involved construction of ‘guide bunds’. The project required about 505 hectare of land, which was acquired across 19 villages. Major earthworks and strengthening of the north and south dykes were completed by June 2011.

What are the advantages of Welded Bridge?

Bogibeel is India’s first and only fully welded bridge construction. It is also for the first time European codes & welding standards were adhered to in the construction of a bridge in India.

Normally in a steel bridge construction, bolts & rivets are used, which needs periodic replacement due to shear failure over traffic loads. Construction of trusses using welding makes the connection between the components a permanent one, thereby eliminating the above failures. Welded bridge not only reduced the maintenance cost but also adds to the longevity of the superstructure. It is estimated that Bogibeel Bridge is durable and serviceable for 120 years.

Describe the ‘Supply-Chain Management’?

Construction supply chain is a network of suppliers, manufacturers, assemblers, sub-contractors, retailers, customers and other stakeholders. The main objective of effective supply chain management is to reduce the handling costs and on-site storage. Enterprise Resource Planning (ERP) solutions, such as System Applications & Products (SAP), implemented at all HCC project sites offer flexibility in material planning as per the construction sequence and help overcome challenges during execution. This, in turn, minimises the idling time of equipment and material inventories and enhances the efficiency of operations.

HCC follows the Just-In-Time (JIT) inventory system where it produces or acquires materials and products as per demand. This is a key component of its supply chain.

One of the major challenges at most construction sites is logistics management, which depends on the availability of various transporters and modern tracking systems. It allows a project manager to select the right transport mix to bring heavy equipment or material to the project site and improve delivery time. At the Bogibeel Bridge project, the team used a combination of rail and road transport to deliver 80,000 tonnes of steel plates from various parts of the country to the remote project site in Assam. The orders for extra wide plates were placed in advance as per the design of the superstructure. In this way, the team avoided any possible mismatch of material and ensured qualitative and timely execution of the job.

Steel plates and sections were procured mainly from three sources i.e. JSPL, Essar & SAIL. Of these 80,000 MT, approximately 20,000 MT (25% scope) was categorized as ODC (Over Dimension Cargo) and attracted special measures for transport to the project site from the sources in Hazira and Angul which were more than 3200 km and 1800 km away respectively. The average lead time of procuring these materials is 4 months. Procurement plan was made according to minimum order quantity required for thickness-wise also estimating future market price trends as the order lot sizes ranges from 3500 MT to 10000 MT.

Spherical bearings were inspected at Germany, shipped to China for load testing and then shipped to Bhopal for the refitting of tested bearings and then finally shipped to project site. The lead time of such consignments is 6 months. Average daily consumption of welding wire was to the tune of 2000 kg per day; Grinding wheels around 5000 per day; Argon + Co2 shielding gas more than 200 cylinders per day; O2 cylinders around 500 per day and around 50 BMCG cylinders per day. Besides 4,50,000 Shear studs were imported from Nelson, USA, (lead time of 3 months), High Strength Friction Grip bolts for around 7,00,000 quantity were manufactured at different sources in India and Diamant MM1018FL gap compensation were imported from Germany (lead time of 3 months). The team achieved perfect synergy between each of these project element procurement and achieved uninterrupted construction flow.

What are the benefits of the bridge?

Defense Boost: The Bogibeel Bridge will be a big boost for the defense forces as it will provide rapid connectivity to areas near the India-China border. This means quicker movement of troops and heavy weapons systems.

Time Savings: Bogibeel Bridge’s biggest benefit is the time that it is going to save. As of now a train journey from Arunachal Pradesh to Assam’s Dibrugarh requires a 500 km detour via Guwahati. Now, the journey will be reduced to less than 100 Km. Also, the train journey between Delhi and Dibrugarh will also come down from 37 hours at present (via Guwahati) to 34 hours – a reduction of 3 hours.

Direct Access to Districts of Upper Assam: The bridge will provide direct access to the districts of Upper Assam from the rest of the country through the North bank and will do away the need to take tortuous route through Guwahati in the South bank.

Boost Tourism: Tourist places of Arunachal Pradesh will become more accessible and give a fillip to the tourism industry. The bridge will also cut down the distance to the border with China by 10 hours.

Better Medical Facilities: Dibrugarh district also houses prestigious Assam Medical College. The bridge will benefit the intra/inter-state transportation of medical patients seeking treatment in Dibrugarh. Currently, if any emergency of super speciality kind arises along the northern bank, the patients need to rely on boat ferries for transportation which can be very cumbersome and dicey.

Economic Benefits: The Bridge, by connecting two very important highways of Assam namely the NH37 and NH52, will contribute in enhancing the intra-state and inter-state trade ecosystem. At present, any cargo generated on both the sides consumes at least 10 to 12 hours before it reaches its destination.

The Bogibeel Rail-Road link will significantly reduce this trans-shipment time and will take maximum 2 hours, thus saving the unnecessary extra cost of transportation and time too.