Leading The Revolution Of Green Construction

Kirby Building Systems & Structures India Pvt. Ltd.

Building Usage – Pumps Manufacturing Facility; Industry – Pumps (Capital Goods)

This new facility of KSB Limited is housed in an overall plot area admeasuring 100,000 sq. meters. The first phase is with a covered area of 16500 sq. meters and the building part of which has been completed in a record time of 6 months and has had the credit of a “zero accident” incidence in over 836,000 man hours invested in various activities during the construction.

Key features of this plant is the material handling capabilities of up to 80 tons; power availability expandable up to 10 MW from 6MW; can easily handle products up to 13 meters height; Assembly and final aggregate is in a dust free environment by pressurizing the shop; State – of – the –art testing facilities include – hot water testing; thermal shock; dry running; string test etc.; zero discharge facility making the plant environment friendly.

Water is the prime necessity of life in nature. It is also the driving force behind every civilization all around the world. KSB Ltd’s pumps and valves provide and distribute water to private, public and industrial buildings. They solve heating and air-conditioning problems. Chemical, petrochemical and many other companies use them to transport aggressive, corrosive, explosive, solids-laden and viscous liquids. KSB products deal with industrial and municipal waste water.

Access to energy is fundamental to our civilization. Economic and social development is fueling a growing demand for reliable, affordable and clean energy. Moreover, nearly 1.3 billion people or roughly a quarter of the world’s population, lack access to modern energy services.

With changing demographics and rapidly increasing urbanization and industrialization because of rising middle class leading to higher consumption, demand for these pumps has also increased accordingly. This facility will enable the company to meet this demand and provide the solution as and when needed.

Building Statistics

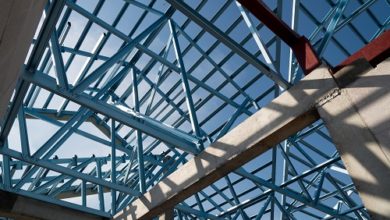

Building Type – BC2 (High Bay-Low Bay) + BC1 (High Bay); Width – 104.46 meters; Length – 114 meters; Height – 13.5; Roof Slope – Curved; Roof Sheeting – 0.5 mm Kirby Standing Seam (KSS-600) Color Coated Galvalume; Wall Cladding – 0.5 mm Kirby Wall Color Coated Galvalume; Rockwool insulation with weld mesh for roof area; Designed as per IS 800-2007 (LRFD method); Load combinations IS:800-2007

- The mainframe rafters and exterior columns are rigidly connected to each other (using moment connections).

- Column base condition is combination of fixed and pinned base

- The lateral stability of the building is provided through the frame action of the main frames.

- The longitudinal stability of the building is provided through the truss action in the cross-braced bays of the building. Tube bracing is considered during designing.

- The roof purlins are continuous beams supported at rigid frame locations and span is equal to the bay spacing of the building.

- The sidewall girts are continuous beams supported at rigid frame location and span is equal to the bay spacing of the building.

- The end wall girts are continuous beams supported at wind column locations.

- The roof and wall sheeting provide lateral support for purlins and girts.

- The analysis & design of all main frames is carried out by using STAAD-Pro Software

- The secondary members (Purlins & Girts) are designed using excel sheets.

- Crane beam is designed for 20 MT EOT Crane

- Cable tray support structure with supports at every 2.0m at one level with 600 mm Clear Projection and bracket at 6.5 m level with loading of 150Kg per running meter.

- Considered 3 Nos. platform below raised roof inclined portion

- 2.2 m projection from steel line X 8.0 m for ECU installation for Load of 200Kg/Unit -2 Units/platform.

- This platform is having Z type Aluminum Louvers from Front to close these ECU units.

- Considered chequered plate for platform.

- Considered support structure for Lightening arrestor.

- Considered rafter to rafter beams at 6 locations with 8.0m bay spacing for hanging HVLS Fans with loading of 150Kg/Fan.

- Considered 1 line of girt for providing colour band.

- Crane walkway considered with Cage ladder.

- Shot Blasting + 2 Coats of Primer at Factory and Two coats of Synthetic Enamel paint at Factory. 1 Mist Coat /for Touchup at Site

All the buildings are provided with necessary accessories such as skylights, wall lights, windows, doors, ridge ventilators, turbo vents, sliding doors, etc. to provide a natural and pleasing working environment for all the occupants.

Steel has the ability to withstand some of the most damaging weather conditions as well as being fire resistant by variety of methods / techniques such as fire-retardant paints, column & beam encasement, etc. High grade steel material is used in the complete structure which is more than 70% recyclable. All the raw material such as plates and coils are procured from India’s leading steel manufacturers or imported as per the customer’s specifications and then processed as per the shop floor drawings with different dimensions and modularities with strict control on accuracy.

The structural form of the building is good in appearance and can withstand any adverse conditions and still stand tall without any damage.

PEB is one of the first choices when it comes to sustainable and eco-friendly buildings. Kirby India is in the forefront of this innovation and is leading the revolution of green construction in the country through its PEB technology. These buildings are cost effective, energy efficient and provide better quality environment as they are cooler in hot conditions due to the favourable roofing material, suitable insulation and natural ventilation. The use of skylights and solar panels mounted on rooftops of industrial buildings will meet daylight and captive power requirements which will reduce their dependence on power supply from other sources and at the same time reduce emissions. Effective usage of insulation material, louvers and other materials also help in making PEB one of the most preferred green buildings.

Project summary

Client Name: KSB Ltd; Steel Solution Provider – Kirby Building Systems & Structures India Pvt Ltd; Architect – Architects United; PMC – AMs Project Management Consultant; Tonnage – 820 MT; Area – 6,520 Sqm; Building Value – Approx. INR 9.2 crores; Jobsite – Khandala, Dist. Satara, Maharashtra