“We see a buoyant sentiment in market”

Ramesh Babbar, President & Director, Columbia Machine Engineering (I) Pvt. Ltd. tells about the company’s preparation for bC India. He optimistically talks about the market growth and company’s performance.

- Your overview on the growth of industry in general and your company business in this financial year?

We are 100 % Indian subsidiary of Columbia machines Inc USA. The last few months have seen excellent growth in the volume of our core business i.e. concrete block making machines when compared to last year same period. We see a buoyant sentiment in market. We would certainly be ending up our year with very positive outlook. We at Columbia have a clear mandate to meet both current and latent needs of the customers under our ‘customer satisfaction’ strategy and with this in view we shall be able to do in most effective manner. Also we are very optimistic for the next financial year as well, though elections are coming up which can severely impact the contraction and real estate sectors.

- Tell us in detail about the versatile product line of Columbia Machine Engineering and role of R&D to beat the competition.

Today, with over 15 years of local manufacturing at Vadodara in Gujarat, we offer the most versatile, innovative concrete products equipment in the industry. In India, our existing Concrete Product Machine Model SPM20 provides our customers a plant with an ideal combination of a high technology machine with medium capacity and low investment in pallet and product handling. Its simplicity and ease of installation/dismantling makes it an ideal solution for project works. The Model SPM30 machine is provided with a unique Rack Loader /Unloader Model UL30 made in India with technology from Columbia Machine, USA. UL 30 provides completely automatic loading and unloading the production pallets in to the Racks. Further cured products are automatically cubed on wooden pallets using the Plate Style Cuber PSC 200 again made in India with technology provided by Columbia Machine USA. This increased Pallet and product handing efficiency and improves productivity as well as reduces product handling damages drastically.

Please tell us about customer support services including training, spare parts supply and regular maintaining issues?

We have a strong, well experienced customer service team based at our factory at Vadodara. This service support along with local availability of all spares for our equipment has given us an edge over our competitors. More than 80% of the spare parts are ready in stock at our factory in Vadodara and is dispatched within 8 hours. We provide in house training to customer operators as well as mix design technology. We also have Annual Maintenance Contracts with our customers.

- Core competence of Columbia Machine Engineering that gives it an edge over others?

Most concrete block machine manufacturers use Table vibration technology. This is commonly found on big board or large pallet concrete products machines. It uses vibrators which are connected to impact bars; these bars strike the bottom of the production pallet to create vibration throughout the product. It is inherently inefficient due to the random motion, which leads to poor height control and non-linear product densities and textures. Columbia’s patented vibration technology CVT combines 80 years of innovative engineering and field proven designs with industry leading manufacturing capabilities. CVT enables producers to create the highest quality and widest range of products in the world.Uniform product height, consistent product weight, superior appearance, reduced cement requirement and sharper product edges are some of the advantages of CVT over traditional table vibration technology.

- Tell us about your preparations for bauma conexpo India. What excite you about this show?

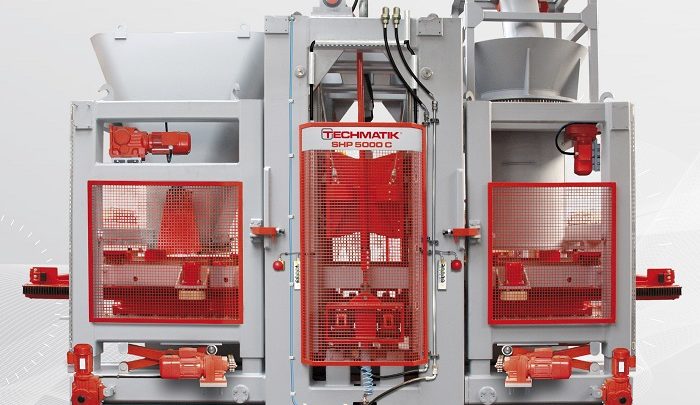

Bauma ConExpo is the largest show for Construction Machinery in North India with a good number of local and foreign Exhibitors. It is well marketed and has been able to attract a significant number of visitors from the relevant industry segments. Our aim would be to meet all those prospects who are keen to enter into this business and brief them about our latest offerings to meet their requirements and provide complete solutions. We shall be displaying our newly designed and manufactured PLANETARY MIXER in this show. This is new equipment to our range and is exclusively made in India from Technology from our group Company TECHMATIC of Poland.